CNC Daim iav Spark Tshuab

Parameter rooj

Muaj peev xwm parameter table

| Yam khoom | Chav tsev | Tus nqi |

| Table Size (Long × Dav) | mm | 700 × 400 hli |

| Sab hauv Dimension ntawm Kev Ua Kua Tank (Long × Dav × Siab) | mm | 1150 × 660 × 435 hli |

| Liquid Level Adjustment Range | mm | 110-300 Nws |

| Lub peev xwm siab tshaj plaws ntawm kev ua kua Tank | l | 235 |

| X, Y, Z Axis Travel | mm | 450 × 350 × 300 hli |

| Maximum Electrode Nyhav | kg | 50 |

| Qhov loj tshaj workpiece | mm | 900 × 600 × 300 hli |

| Maximum Workpiece Nyhav | kg | 400 |

| Yam tsawg kawg rau qhov siab tshaj plaws ntawm qhov chaw ua hauj lwm mus rau lub taub hau electrode | mm | 330-600 Nws |

| Positioning Accuracy (JIS Standard) | ib m | 5 μm / 100 hli |

| Repeated Positioning Accuracy (JIS Standard) | ib m | 2m ua |

| Zuag qhia tag nrho Dimension ntawm Tshuab Tool (Length × Dav × Qhov siab) | mm | 1400 × 1600 × 2340 hli |

| Tshuab Nyhav Approx. (Length × Dav × Qhov siab) | kg | 2350 |

| Daim Ntawv Qhia Dimension (Length × Dav × Qhov siab) | mm | 1560 × 1450 × 2300 hli |

| Reservoir Volume | l | 600 |

| Lim Txoj Kev Machining Fluid | A | Exchangeable Paper Core Lim |

| Maximum Machining Tam sim no | kW | 50 |

| Tag Nrho Lub Zog Input | kW | 9 |

| Input voltage | V | 380v ua |

| Qhov Zoo Tshaj Plaws Roughness (Ra) | ib m | 0,1m ua |

| Tsawg Electrode Poob | - | 0.10% |

| Txheej txheem txheej txheem | Tooj / hlau, micro tooj liab / steel, graphite / steel, steel tungsten / steel, micro tooj liab tungsten / steel, steel / steel, tooj liab tungsten / nyuaj alloy, tooj liab / aluminium, graphite / tshav kub resistant alloy, graphite / titanium, tooj liab / tooj liab | |

| Txoj kev Interpolation | Txoj kab ncaj nraim, arc, kauv, rab phom xyoob | |

| Ntau yam nyiaj pab | Cov kauj ruam yuam kev them nyiaj thiab qhov sib txawv yog ua rau txhua axis | |

| Tus naj npawb ntawm Control Axes | Peb-axis peb-txuas (tus qauv), plaub-axis plaub-txuas (yeem) | |

| Kev daws teeb meem ntau yam | ib m | 0.41 ib |

| Yam tsawg kawg Drive Unit | - | Kov npo, U disk |

| Txoj kev nkag | - | Qauv: RS-232 |

| Zaub hom | - | 15 ″ LCD (TET * LCD) |

| Manual Control Box | - | Standard inching (ntau-theem hloov), pab A0 ~ A3 |

| Txoj hauj lwm hais kom ua hom | - | Ob qho tag nrho thiab incremental |

Qauv Taw Qhia

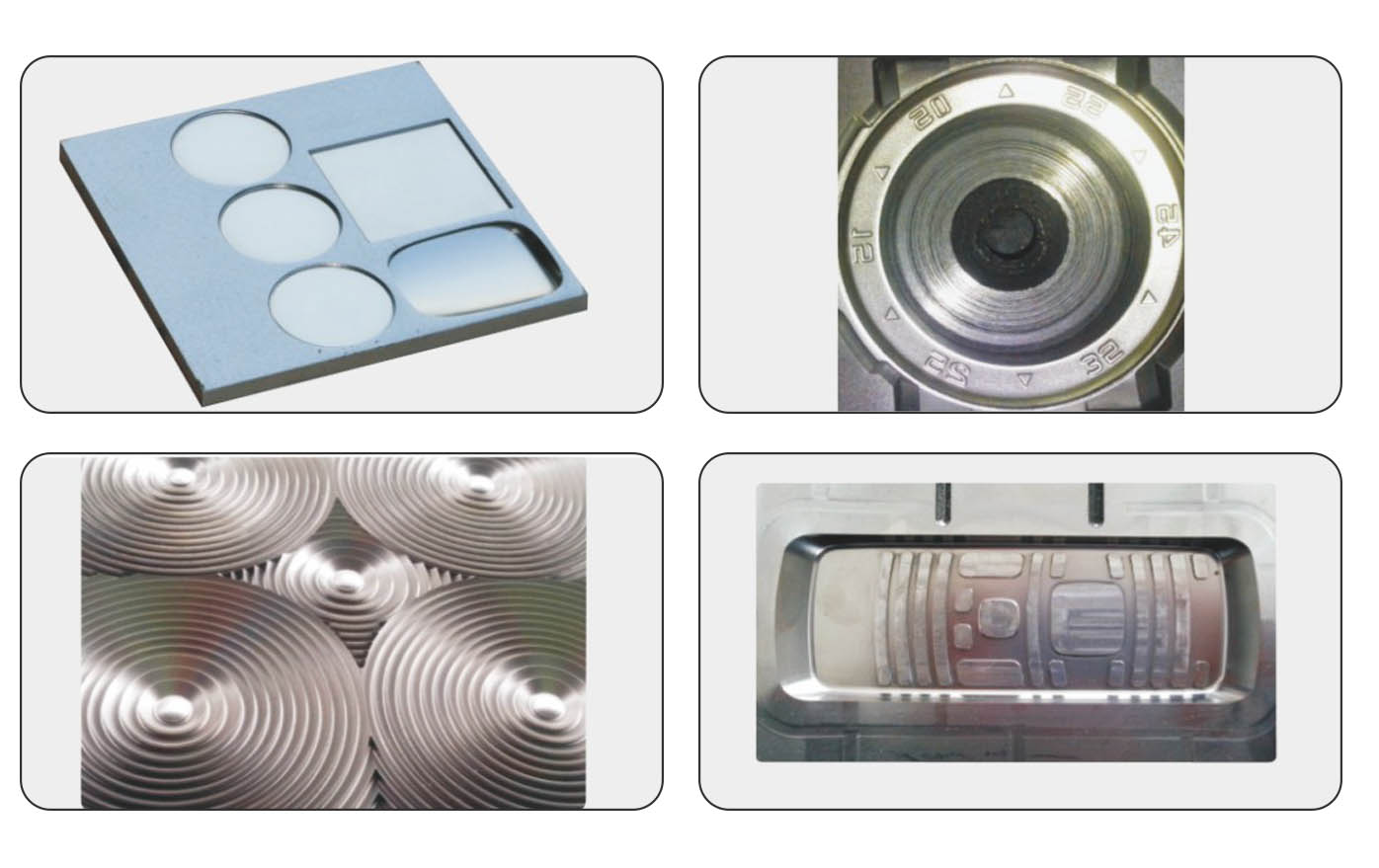

Comprehensive Processing Examples (Daim iav tiav)

| Piv txwv | Tshuab Qauv | Khoom siv | Loj | Nto Roughness | Cov yam ntxwv ua | Lub Sijhawm Ua Haujlwm |

| Daim iav tiav | A45 | Tooj liab - S136 (Ntshuam) | 30 x 40 mm (Cov qauv) | Ra ≤ 0.4 μm | High Hardness, High Gloss | 5 teev 30 feeb (Cov Qauv) |

Saib Case Mould

| Piv txwv | Tshuab Qauv | Khoom siv | Loj | Nto Roughness | Cov yam ntxwv ua | Lub Sijhawm Ua Haujlwm |

| Saib Case Mould | A45 | Tooj - S136 Hardened | 40 x 40 mm | Ra ≤ 1.6 μm | Uniform Texture | 4 hnu |

Razor Hniav Mould

| Piv txwv | Tshuab Qauv | Khoom siv | Loj | Nto Roughness | Cov yam ntxwv ua | Lub Sijhawm Ua Haujlwm |

| Razor Hniav Mould | A45 | Tooj - NAK80 | 50 x 50 mm | Ra ≤ 0.4 μm | High Hardness, Uniform Texture | 7 hnu |

Xov tooj Case Mould (Mixed Powder Processing)

| Piv txwv | Tshuab Qauv | Khoom siv | Loj | Nto Roughness | Cov yam ntxwv ua | Lub Sijhawm Ua Haujlwm |

| Xov tooj Case Mould | A45 | Tooj - NAK80 | 130 x 60 mm | Ra ≤ 0.6 μm | High Hardness, Uniform Texture | 8 hnu |

Sau koj cov lus ntawm no thiab xa tuaj rau peb